This article has been written by DaVinci Aviation, a start up that has been working on a new business jet design. DaVinci Aviation is looking for partners in order to take their idea to the next development phase and they welcome your help. Feel free to contact them directly using the form bellow. If you wish to pitch your start up idea to the community, please contact us here.

Table of Contents

THE 21st CENTURY BUSINESS JET IS NOT YET THERE!

Air transport is perhaps one of the industries that are the most under scrutiny for its impact on the environment, rightfully so or not, for that matter. The global warming is instigating the world governments to define and enforce “zero net emissions” policies. In aviation those policies are being enforced by more and more stringent regulations which will forge the next generation of aircraft and propulsive systems for commercial aviation. So, green aviation seems to be a next obligation of mankind with the business opportunity that comes with it.

Indeed, in the last few years more and more entrepreneurs, startups, investors and the large industry itself have set in this race to deliver a greener aviation. On one side countless (and still counting) little electric air vehicles concepts with many little propellers distributed all around have been proposed by as many entrepreneurs and their startups to deliver the UAM (Urban Air Mobility).

Given the challenges of the missing regulation, let alone those of the missing infrastructure (both still a long way to come) and of safe operations in highly populated areas, it feels a little like UAM is a freshly invented need to give the electrified air transport a chance at least at urban scale, the only one that batteries with their current limitations might be capable of. Nonetheless investors put non negligible amounts of cash in this kind of startups.

On the other one, large aircraft manufacturers and research institution have (long) initiated studies of new exotic transport aircraft configurations in the quest for more efficient (i.e. less fuel demanding) aircraft.

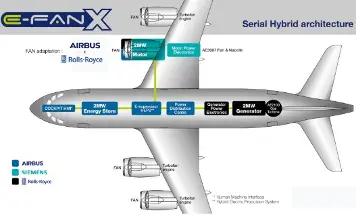

And at the same time, along with the large engine manufacturers, they’re trying to figure out how to integrate novel hybrid propulsion systems within current airframes without giving up too much of the volume and weight for payload.

WILL ELECTRIFICATION EVER MAKE AVIATION ANY GREENER?

In order to fly more efficiently (and therefore more environmentally caring) aircraft weight is in the end one of the most important factors and must be kept down. It’s really unclear from today’s perspective how lots of additional hardware in the current e- and hybrid-propulsion concepts, such as:

- electric engines (mostly made of iron and copper),

- high-voltage looms,

- heat dissipating devices,

- power converters

- gas generators for in-flight recharge of batteries,

- Batteries weight (for every kilogram of kerosene ~11kg of batteries are required to generate the same usable thrust over the same duration),

- which does not dissipate with depletion (opposite to fuel weight)

can make an electric aircraft efficient at all.

Let’s say that we were at the verge of solving the hardware weight and volume problems just mentioned above and of obtaining an increase of energy density by a factor of 13 (currently ~300Wh/kg – required to replace fuel in long range flight: ~4000Wh/kg) of the batteries. Could we electrify aviation right away?

The next question is: where would we recharge a vast number (millions?) of batteries from? Today we could at best plug them in the electric power nets which are mostly powered by fossil and nuclear fuel.

And then, where would we get from all of the minerals to build those many batteries and replace them as they get depleted (battery life is of a few years only).

In order to really fly green with batteries another set of major problems should be solved first:

- Create the global infrastructure to recharge batteries from renewable energy sources (wind, sun, water…). Burning some sort of fuel in a power plant, generate electric energy, store it in batteries and then claim it from the battery itself is a less efficient process than directly burning fuel in an engine combustion chamber.

- Find a way to extract and process the minerals for the batteries on vast scale to power aviation (and automotive for that matter) in an as much “0 net emission” fashion.

- Find a way to effectively recycle the build materials of the depleted batteries. Failing in this last challenge would soon create an additional global pollution problem as overwhelming as the plastic waste itself.

Honestly we don’t see anyone, neither governments nor the fans of electrification tackling these immense challenges, yet.

Even though all of those problems might get solved one day so to enable a greener aviation, from today’s perspective no practical application is going to be at hand any time soon, and perhaps, given the proportions of the many technical and political challenges, it won’t be for the next fifteen to twenty years. And if this is a blow for the environment, so it is for the business opportunities.

AN OPPORTUNITY FOR GREEN AVIATION AND FOR BUSINESS EXISTS NOW

In this rush none seem to have realized that there’s a whole branch of aviation, the business aviation, where a hidden yet a huge opportunity is available right now to fly greener, therefore fulfilling our obligation toward our home planet and to make large profits at the same time.

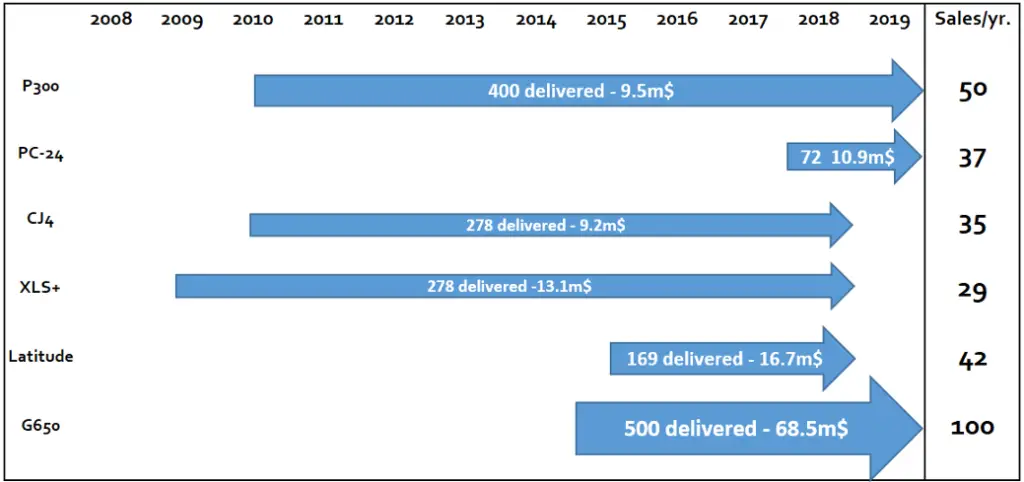

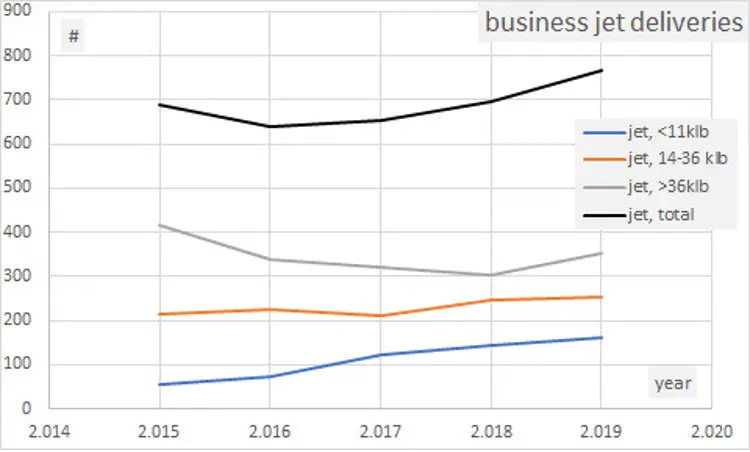

That of the business aviation is quite a profitable market for the active manufacturers in this segment.

These are a few but very good examples over the last ten years of how those manufacturers could enjoy a highly satisfying flow of orders from the very entry into service date of their new products.

In general the market of the BJ’s has been very lively over the past decade and it’s expected to grow even more in the future, especially if China’s authorities will make their airspaces available to privately own aviation.

Last but not least, if the immediate effect of the pandemic has hit the whole aircraft industry as well through the supply chains, the reaction of wealthy individuals and corporations to this COVID time is that to look at private aviation as a way of avoiding big crowded commercial aircraft and airport terminals.

On the other hand, this market is fully occupied by a bunch of companies, that for brand reputation and technology we could call the Ferrari and Porsche of aviation. They have left no niche in no segment of it.

Where is then this opportunity to start making the aviation greener now and of making profit with it?

AREAS FOR RADICAL INNOVATION

It might be surprising, but most of the aerodynamic and structural elements of a modern business jet haven’t changed much since the introduction of the first private jet in the sixties of last century. Some of the most important selling points of a BJ, such has the uninterrupted cabin floor and cabin height, drive the aircraft layout in a way that there’re inherent inefficiencies (structurally and aerodynamically) of that kind of design.

Well, imagine for a moment that you can bring to a market full of “carbon copied” products barely distinguishable from one another, an airplane that with its elegant but futuristic lines seems to emerge straight from a science fiction movie. And imagine that this aircraft can offer

- improved by up to 30+% specific air range (how many miles an aircraft flies per pound of burnt fuel) with respect to existing aircraft

- reduced CO2 emissions accordingly

- provide more cabin comfort and amenities to the passengers than the existing designs do

- to create a business opportunity of 500+m$/year in the business jet market segment

- and be a forerunner for reshaping the commercial aviation too

- the potential to accommodate any kind of future propulsion systems (fully electric, hybrid, hydrogen…) should they become available and really be more efficient than the current ones.

At DaVinci Aviation we set off with these goals in mind. We reconsidered from the ground up the elements of the current designs and we reinvented the business jet to a truly 21st century, environment caring kind of aircraft.

We think we succeeded in this process and our performance projections, based on our engineering work, show a significant advantage of our concept, w.r.t the aircraft in two market segments at once (light and mid-size business jets).

We can offer a greener airframe by design, i. e. lower consumption (and therefore emissions) at equal or higher cruise speed than existing aircraft in the two above market segments.

In light of the growing environmental awareness of individuals and governments, a greener aircraft means wider acceptance by the general public, certifying agencies, political leaders, environment caring businessmen and corporations.

THE WAY AHEAD

We have developed a design at the concept stage. The conceptual design is a common and fundamental practice at each large aircraft manufacturer to establish the soundness of a concept from both the engineering and marketing standpoints before proceeding into the demanding preliminary design phase. This is what we could achieve with our own resources.

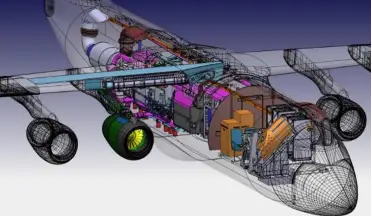

The very next steps are fundamental and yet not very financially and time demanding: a more in detail verification of our results is required to confirm our predictions and consolidate the concept potential, for instance in special missions such as air ambulance. To achieve this goal virtual aerodynamic and structural models of the aircraft must be created. The aerodynamic model would be run in a virtual (mathematical) wind-tunnel in order to predict the aerodynamic drag and other stability characteristics of the proposed configuration with greater accuracy. The structural layout model would provide an overview of the structural feasibility, the general layout of the aircraft elements, the required materials technology and a more accurate estimate of the aircraft empty weight. The financial effort of this phase might be in the order of 250k€.

Assuming that the concept would pass the scrutiny with flying colors, as we expect it would, a financial and technical machine, the company, would have to be created, capable to bring to life certify and market the concept.

A project like this would be in the order of the 500m$ on a time scale of ~6 years distributed roughly as follows:

• Preliminary Design to PDR – 1.2 year – 70mln

• Detailed Design to CDR -1.5 years – 90m$

• 1 prototype build – 8m$ – 3 required

• Development (engineering & flight test) – 2 years – 180m$

• Certification (engineering & flight test) and marketing – 1.2 years – 110m$

These numbers apply to an experienced and well organized manufacturer, i.e. a manufacturer with previous experience in design, build, certification and marketing of a complex aircraft. However, startups such as Boom, Tesla, Blue Origin and SpaceX are the living proof that great visions make no goal hard enough that can’t be achieved.