Today’s competitive global marketplace requires manufacturers to constantly boost their efficiency by tracking production in real-time and analyzing the gathered data to optimize its output. In the aerospace industry, companies must adapt to new technologies and keep up to speed on the latest equipment, processes, and regulations. In other words, they must operate at peak performance, and a manufacturing execution system (MES) can help with that.

Table of Contents

What Is MES Software?

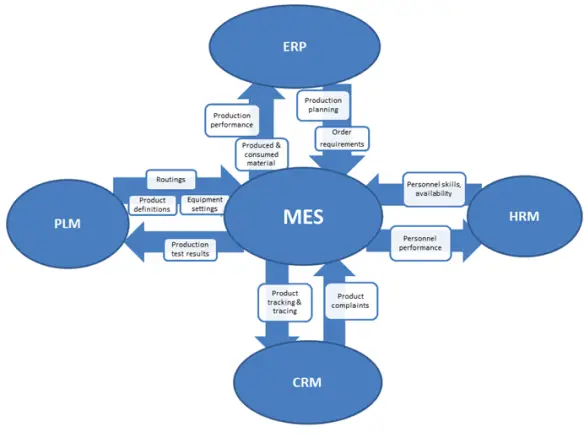

Manufacturing execution systems are software solutions used by manufacturers across all industries to monitor the production process and systematically and proactively improve its quality and efficiency, connecting real-time information from multiple plants, sites, and vendors and ensuring complete visibility and control across the enterprise.

Managers use MES software to monitor efficiency and implement production plans, shop floor employees use MES to follow their work schedules, and IT employees use MES to support the overall IT strategy and seamlessly connect plant equipment to plant operations.

Main Features of MES Software

Modern MES software solutions boast many useful features spanning the entire product life cycle:

- Data collection: The chief responsibility of MES software is to collect data from multiple sources to provide real-time visibility into equipment and processes across the entire plant.

- Production planning: With real-time inventory updates and raw material tracking, MES software helps reallocate materials to ensure smooth production even during high demand periods.

- Performance analysis: MES software can analyze key performance indicators to help maintain satisfactory performance levels and reveal how they could be improved.

- Maintenance management: Aerospace manufacturers that want to compete on the global stage can’t afford to wait for equipment to malfunction. MES software helps accurately plan preventative machine maintenance, reducing downtime, and minimizing production interruptions.

- Change management: Change is unavoidable, and something all manufacturers have to deal with. MES software delivers the flexibility to model, change, and enforce complex processes in a timely manner.

Aerospace Specific Needs

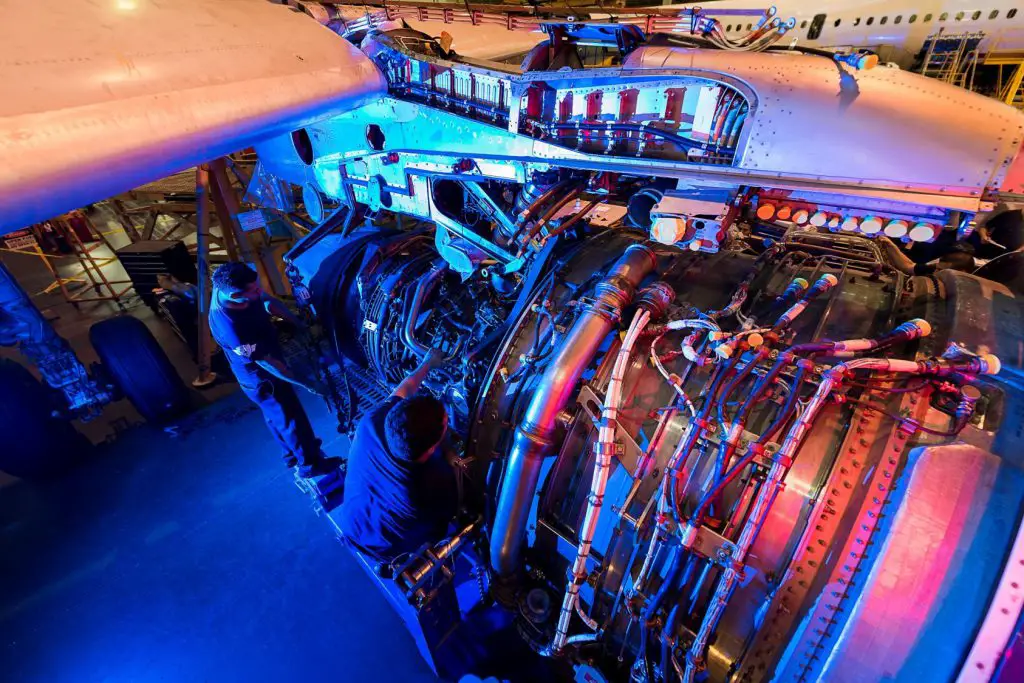

Manufacturers in the aerospace industry have their specific needs that stem from the unique nature of their industry.

Because aerospace manufacturers work with high-value materials, they have a need to achieve high first-time pass rates and minimize waste. MES software can reveal which processes are the most inefficient and support their improvement.

The complex nature of aerospace supply chains requires aerospace manufacturers to work collaboratively in order to meet their strategic and financial goals when building next-generation aircraft. MES software supports collaboration by gathering information from multiple plants, sites, and vendors and making it available for strategic planning and swift decision making.

Last but not least, the aerospace industry has an obligation to conform to precise specifications and comply with stringent regulations, which is possible only with an MES software solution capable of providing complete visibility across the entire plant and product life cycle.

How to Select MES Software?

Now that we’ve described some of the main features of MES software and the specific needs of aerospace manufacturers, it’s time to talk about what should be considered when selecting MES software.

To start with, not every manufacturer needs MES software because many smaller manufacturers don’t have production operations that are large enough to justify implementing MES software. Such manufacturers are better off relying on their existing software until their profit margins allow for this type of investment.

Manufacturers that are ready to implement MES software should select such a solution that can prepare their factory for the future and the inevitable arrival of Industry 4.0 and technologies such as the Internet of Things (IoT), augmented reality (AR), and artificial intelligence (AI).

Getting assistance from Industry experts:

Connecting with Aerospace & Defense industry experts is one of the alternative solution in order to ask the different question that you have and to seek the advices that you need. Feel free to have a look at the services providers that we listed for you in the following categories:

Top 20 Best MES Software for Aerospace

It may almost seem that the number of MES software solutions aerospace manufacturers can choose from is endless. While having many options available is generally a good thing, it can also make selecting the right one a real challenge, which is why we analyzed the market and created this list of the top 20 best MES software for aerospace.

1. Fishbowl Manufacturing

Offering advanced work orders, manufacture orders, bills of materials, and other tools, Fishbowl Manufacturing (FBM) helps manufacturers maximize efficiency in their production process regardless of how complex their manufacturing needs are. Its features include automated custom, batch, and repair work orders, lot tracking and serial number tracking in work orders, QuickBooks and Xero integration, inventory management, order management, reporting, and much more. The already-impressive feature set of Fishbowl Manufacturing can be further augmented with various plugin products, including Fishbowl Anywhere, Fishbowl Go, Fishbowl SalesPoint, and Fishbowl Commerce.

2. NetSuite

Founded in 1998 with headquarters in Redwood Shores, California, NetSuite is a comprehensive cloud business software suite with extensive MES capabilities, such as integrated inventory, warehouse management, accounting and financial management, and order management, just to name a few. Used by thousands of manufacturers around the world, NetSuite is designed to support rapid growth and mature enough to satisfy the complex needs of aerospace manufacturers.

3. E2 Shop System

Ideal for make-to-order manufacturers, job-based and mixed-mode manufacturers, E2 Shop System gives manufacturers the power and flexibility to access all the information they need to have in order to seamlessly turn quotes into orders while eliminating bottlenecks, improving business performance, and delivering jobs on time. From scheduling to purchasing to shipping, E2 Shop System comes with all the essential MES features without being overly complex and difficult to use. It offers over 200 built-in reports for comprehensive analysis and has many other capabilities that make it stand out.

4. Hydra MES

Hydra is a modular MES by MPDV. It fully covers the requirements of the VDI guideline 5600, which serves as guidance for decision-makers, process owners and users, persons involved in the selection and implementation process, as well as suppliers of software, hardware, and integration systems. Its features include machine data collection, shop floor scheduling, tool and resource management, and quality management. Hydra MES was designed for easy integration into existing production environments, and it has proven to be very effective in helping manufacturers secure their competitiveness with regard to Industry 4.0.

5. FactoryTalk ProductionCentre MES

FactoryTalk ProductionCentre MES helps manufacturers resolve production issues in the shortest time possible by combining an execution system for the plant floor with the rich functionality of application software. Delivering comprehensive production management functionality plus highly developed decision support tools that address the most demanding manufacturing environments, FactoryTalk ProductionCentre MES improves control over quality, speed, and waste, creates a flexible real-time production environment, automates records management, and reduces human error.

6. IQMS MES

IQMS MES software increases visibility and transparency into every aspect of manufacturing operation. Customers who use this leading MES software experience reduced production errors, decreased part lead time, increased company-wide productivity, improved quality compliance, reduce quality losses, and increased production throughput. The company behind IQMS MES has been a market leader since 1993, delivering software solutions capable of solving all production challenges and helping manufacturers proactively make informed decisions.

7. Bluestreak

With its focus on additive manufacturing production, the process of building a three-dimensional object from a computer-aided design model by successively adding material layer by layer, Bluestreak is a suite of production control and quality management tools that revolve around providing real-time processing visibility, production control of each operating step, and integrated quality management. It’s a particularly good fit for manufacturers that are not ready to invest in a full-blown ERP system but would still like to enjoy its benefits.

8. Epicor Advanced MES (Mattec)

Epicor Advanced MES (Mattec) is a real-time production and process monitoring solution for manufacturers that would like to eliminate inefficiencies and make better decisions with accurate, easy-to-read, real-time information. Epicor Advanced MES (Mattec) helps implement continuous improvement initiatives to drive business growth and transform the shop floor into a center of excellence with its advanced capabilities, which include production monitoring, process monitoring, quality management, alerts and notifications, production scheduling, advanced analytics, maintenance management, and energy monitoring.

9. Sepasoft MES

Providing control, traceability, and documentation of the transformation of raw materials into finished goods in real-time, Sepasoft MES includes support for detailed resource scheduling and statuses, dispatching production tasks and sequencing, traceability and genealogy, work-in-progress and inventory details, ensuring quality work instructions and other document control, and performance analyses. This MES software is scalable from a single machine to enterprise deployments, and it can be flexibly tied with an existing ERP system.

10. SAP ME

SAP Manufacturing Execution is a manufacturing execution system software designed to digitize manufacturing processes and integrate business systems using a cost-effective, high-quality, and resource-efficient methodology based on Industry 4.0 technology. Developed by one of the largest enterprise software companies in the world, it comes with first-class customer support and digital advisory services that help manufacturers get more value from their SAP investments.

11. Smart Factory

Smart Factory is an all-in-one MES to production processes monitoring. The solution provides machine data collection and paperless production execution. Production progress feedback can be generated in real-time with digital step by step instructions and documentation in order to guide operators through the manufacturing process. The solution enables changeovers reporting, defect handling, traceability, quality inspections, OEE & KPIs calculation with analysis dashboards and bi-directional ERP integration.

12. Prodsmart

13. Katana

14. Plex Manufacturing Cloud

15. TrakSYS

16. PAS-X

17. Edinn M2

18. Apriso Production

19. FactoryFour

20. WorkClout

21. Global Shop Solutions

Read our other software reviews

One of Aerospace Export’s main guideline is to promote innovative content targeting the Aerospace and Defense industry. Following this guideline, we have been working on few other software reviews that you could directly access here:

Get more information on how we review the different tools

CONTACT US TO REVIEW YOUR TOOL

If you are a tool editor and believe that your tool should be mentioned in our review, please send us a message below and we will get in touch with you. We are constantly updating our ranking with the tools that we believe to be the more relevant for the Aerospace & Defense market.

Learn More